X

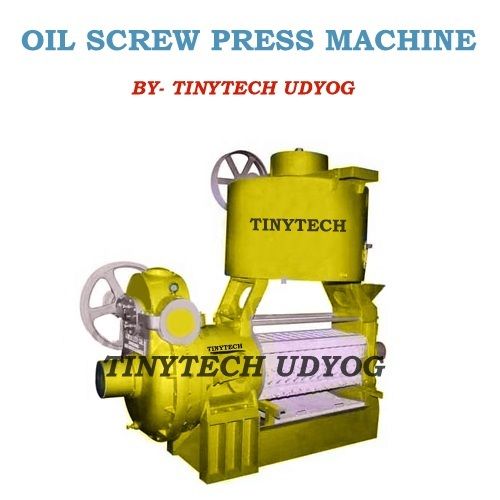

Product Description

Oil Screw Press Machine is used for the oil seeds. The oil bearing seeds and nuts can be mechanically pressed and crushed in our Tinytech Oil Screw Press. The machine is highly precision engineered in terms of design and operation. The entore set of machinery is manufactured by the international set of guidelines so that the quality achieved is excellent. It is a complete versatile machine. It can process many different oil seeds such as peanut, copra, kernels, cottonseed, soyabean, rapeseed, mustard, sunflower etc.

Features of Oil Screw Press Machine:

1. Superior performance

2. Long lifespan

3. High operational efficiency

4. It creates low noise

5. It consumes less energy

Applications of Oil Screw Press:

1. Cooking Oil Production: One of the primary applications of oil screw presses is the extraction of cooking oils from seeds like soybeans, sunflower seeds, peanuts, canola, and sesame. The extracted oils can be used for culinary purposes, such as frying, sauting, and salad dressings.

2. Biodiesel Production: Oil screw presses can also be used to extract oil from oilseed crops like soybeans, rapeseed, and palm kernels for biodiesel production. Biodiesel is an alternative to traditional fossil fuels and can be used in diesel engines.

3. Animal Feed Production: After oil extraction, the residual cake or meal that remains can be used as a valuable protein-rich ingredient in animal feed production. This is particularly common for oil seeds like soybeans and cottonseeds.

4. Cosmetic and Personal Care Products: Oil screw presses are used to extract essential oils and carrier oils from plant materials for use in cosmetics, perfumes, and skincare products. Common sources include lavender, jojoba, and rosehip seeds.

5. Industrial Applications: Some industries utilize screw presses to extract oils or chemicals from various materials for industrial processes. For example, screw presses can be used to extract oil from algae for biofuel production or chemicals from botanicals for pharmaceutical purposes.

6. Oil Refining: While screw presses primarily focus on oil extraction, they can be part of the initial processing step in oil refining. After extraction, the oil often undergoes further refining processes to remove impurities and improve quality.

7. Small-Scale Oil Production: Oil screw presses are commonly used by small-scale farmers and artisanal oil producers to process locally grown oilseeds into edible oils or other valuable products for local consumption or sale.

8. Research and Development: Oil screw presses are also used in research and development settings to study oil extraction processes and develop new techniques for improving oil yield and quality.

9. Oilseed Processing in Developing Regions: In many developing regions, oil screw presses play a crucial role in helping small-scale farmers and communities access edible oils and generate income from locally available oilseeds.

Benefits of Oil Screw Press:

1. Efficient Oil Extraction: Oil screw presses are highly efficient at extracting oil from oil seeds and nuts. They can achieve high oil yields, minimizing waste and maximizing the value of the raw materials.

2. Versatility: Oil screw presses can process a wide range of oil seeds, including soybeans, sunflower seeds, peanuts, cottonseeds, canola, and more. This versatility allows for the extraction of various types of edible and industrial oils.

3. Cost-Effective: These machines are relatively cost-effective to operate and maintain, making them suitable for small-scale and large-scale oil processing operations. They have low energy consumption and require minimal labor.

4. Cold Pressing Option: Cold pressing is a gentle extraction method that preserves the natural flavors, aromas, and nutritional value of the oil. Many oil screw presses can perform cold pressing, which is preferred for certain specialty oils.

5. High-Quality Oil: Oil screw presses typically produce high-quality oil with low levels of impurities and minimal degradation of the oil's nutritional and sensory properties.

6. Continuous Operation: Oil screw presses are designed for continuous operation, allowing for a consistent and uninterrupted oil production process.

7. Reduced Chemical Use: Compared to some other oil extraction methods, such as solvent extraction, oil screw presses generally require fewer or no chemicals in the extraction process, which can be more environmentally friendly.

8. Environmentally Friendly: The mechanical extraction process used in oil screw presses is considered environmentally friendly because it does not involve the use of harmful chemicals or solvents that may have adverse environmental impacts.

9. Oil Seed Cake as Byproduct: After oil extraction, the residual cake or meal left behind still contains valuable nutrients and proteins. This byproduct can be used for animal feed, reducing waste and adding value to the oil seed processing operation.

10. Adaptability to Local Agriculture: Oil screw presses are well-suited for small-scale and community-based oil production in regions with limited access to large-scale processing facilities. This supports local agriculture and economic development.

11. Oil Seed Preprocessing: In addition to oil extraction, some screw presses can also perform preprocessing tasks, such as dehulling or seed cleaning, which can improve overall oil extraction efficiency.

12. Reliability: Oil screw presses are known for their reliability and durability, which is essential for continuous production operations.

FAQ:

Q. What is an oil screw press?

Ans: An oil screw press, also known as an oil expeller or screw oil press, is a mechanical device used to extract oil from oilseeds and nuts through a pressing process. It typically consists of a screw or auger that crushes and compresses the oil-bearing materials to extract the oil.

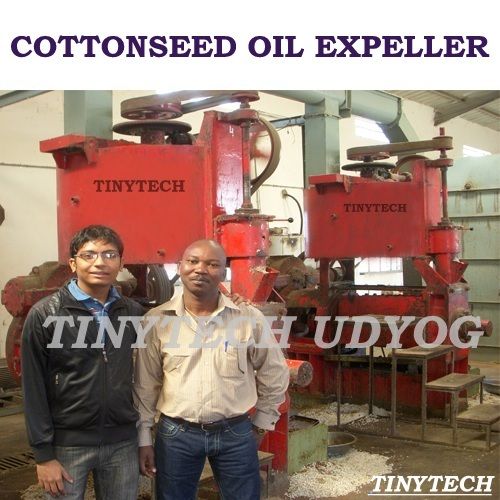

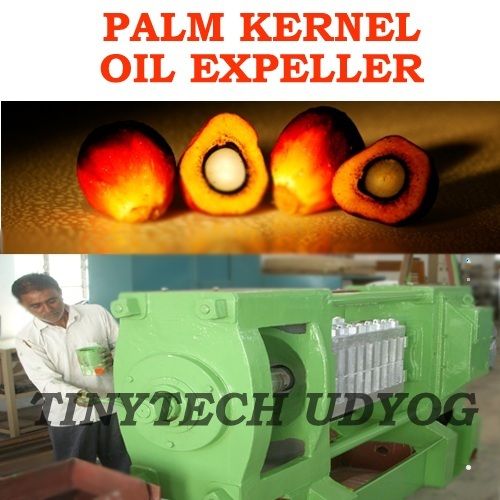

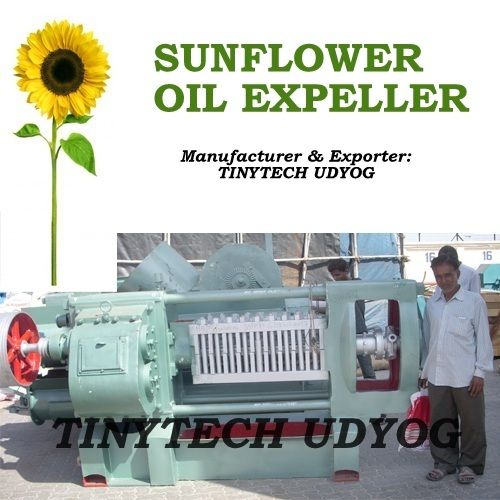

Q. What types of oil seeds can be processed using an oil screw press?

Ans: Oil screw presses can process a wide range of oil seeds, including soybeans, sunflower seeds, peanuts, cottonseeds, canola, sesame seeds, palm kernels, and more. The choice of oil seed depends on the desired oil and its application.

Q. What are the primary applications of oil screw presses?

Ans: The primary applications of oil screw presses include the production of cooking oils, biodiesel, animal feed, essential oils, and industrial oils. They are used in various industries, including food processing, agriculture, and cosmetics.

Q. How does an oil screw press work?

Ans: Oil screw presses work by feeding oil seeds into the press chamber, where a screw or auger rotates and crushes the seeds. As the seeds are compressed, oil is released and flows out through small openings or slots, while the residual cake or meal is expelled from the press.

Q. What is the difference between cold pressing and hot pressing in oil screw presses?

Ans: Cold pressing involves extracting oil from seeds at low temperatures (typically below 60 degree centigrade or 140 degree fahrenheit). This method preserves the oil's natural flavors, aromas, and nutritional value. Hot pressing, on the other hand, uses higher temperatures (usually around 80-100 degree centigrade or 176-212 degree fahrenheit) and may result in higher oil yields but can alter the oil's properties.

Q. Is oil extraction with an oil screw press environmentally friendly?

Ans: Yes, oil extraction with an oil screw press is considered environmentally friendly because it typically does not involve the use of harmful chemicals or solvents. This reduces the environmental impact compared to solvent extraction methods.

Q. What is the byproduct of oil extraction with a screw press?

Ans: The byproduct of oil extraction is often referred to as oilseed cake or meal. It contains residual oil and is a valuable source of protein and nutrients. Oilseed cake can be used as animal feed or further processed for various purposes.

Q. What factors should be considered when selecting an oil screw press?

Ans: Factors to consider include the type of oilseed to be processed, capacity requirements, the desired oil quality, and the availability of maintenance and technical support. The choice of a screw press should align with the specific needs of the operation.

Q. How can I maintain and clean an oil screw press for optimal performance?

Ans: Regular maintenance, such as cleaning the press components, lubricating moving parts, and checking for wear and tear, is essential for optimal performance. The manufacturer's guidelines and recommendations should be followed for maintenance procedures.

Q. Can oil screw presses be used for small-scale or home oil production?

Ans: Yes, smaller-scale oil screw presses are available and can be used for home or small-scale oil production. They are designed to handle smaller quantities of oilseeds and are suitable for artisanal or community-based oil production.

Enter Buying Requirement Details